Weekly programmer with dry contact for boiler control

Gas and electric heating are currently among the most common types of indoor heating systems. In most cases, the heat source in such systems is a boiler with its own built-in automation system.

There are two ways to control the boiler's operation:

- Basic manual control to maintain a specific temperature of the heating medium in the system. This type of control does not account for outdoor temperature fluctuations, requiring manual adjustments. This can lead to operational inconvenience and, in some cases, excessive energy consumption.

- Automated energy-efficient control through the connection of a weekly programmer to maintain a comfortable indoor temperature and save energy by operating according to a weekly schedule. On our website, you can purchase such a dry contact thermostat for boilers — the terneo pro dry contact.

To measure indoor temperature, the thermostat's casing includes a built-in air temperature sensor. A key feature of the terneo pro dry contact is its "dry contact" functionality, enabling connection to heating systems powered by gas or electric boilers.

Why is dry contact important for boiler control?

To control a boiler, the external thermostat's output contacts must not carry 230 V power. When choosing a thermostat for a boiler, ensure it features a dry contact and that the boiler's schematic permits connection to an external thermostat.

In the terneo pro dry contact thermostat, the dry contact is implemented with a separate contact group, ensuring no voltage is present on the output terminals in any state. The "dry contact" prevents 230 V power from reaching the boiler control terminals (5 and 6) from terminals 3 and 4 of the thermostat. For more details, refer to the user manual.

How to connect the terneo pro dry contact to a gas or electric boiler?

Before starting the installation, carefully study the wiring diagram and follow the instructions provided by both the boiler and thermostat manufacturers. Always adhere to safety guidelines. Given the high cost of gas boilers and the strict safety requirements for their operation, it is crucial to connect the thermostat properly! If necessary, consult qualified professionals.

1. Gas Boiler

Before connecting to the gas boiler, we additionally recommend checking for the absence of voltage on the thermostat terminals used to connect to the boiler's automation system.

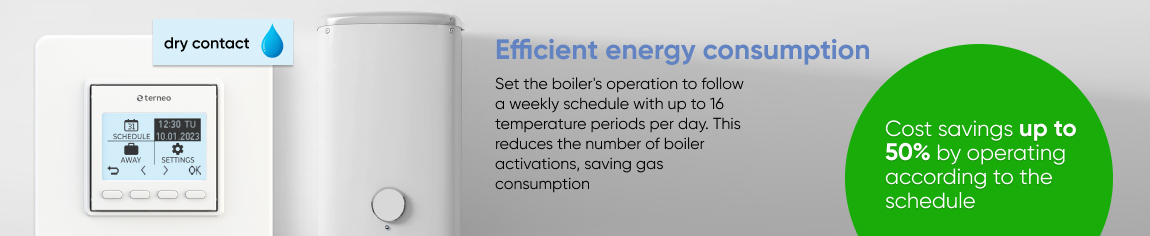

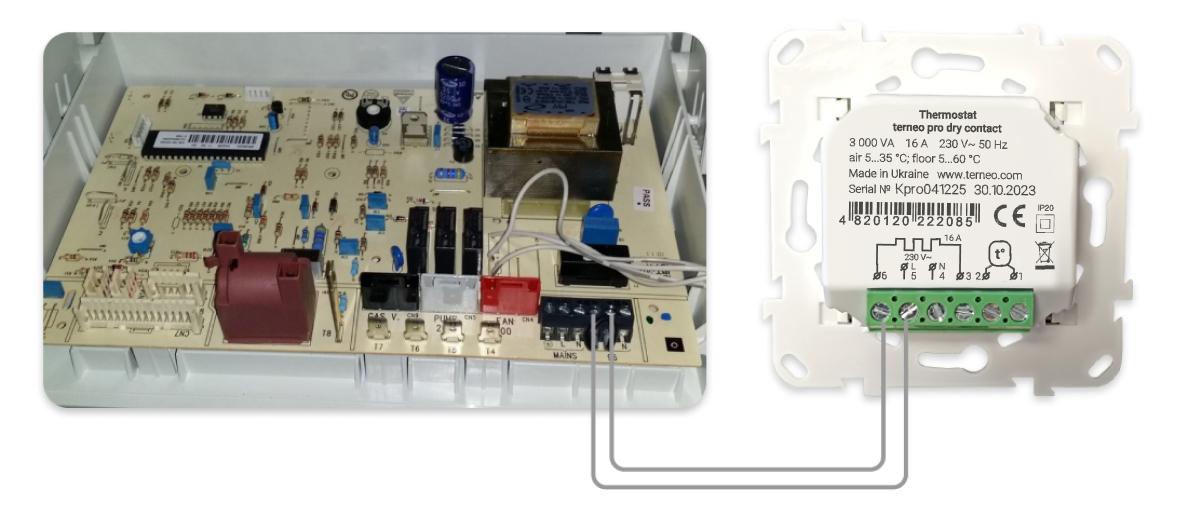

Refer to the gas boiler manual for a diagram indicating the connection point for an external thermostat. Typically, such a connection point is provided via a separate terminal block on the circuit board or an external terminal block (detached terminal), where a jumper is installed in the connecting terminals.

The thermostat is connected in place of the jumper (see Fig. 1). To connect, loosen the screws holding the jumper, remove it, and connect the wires from thermostat terminals 5 and 6 in its place.

Figure 1. Connection on the board

Figure 2. Connection outside the board (external terminal block)

2. Electric Boiler

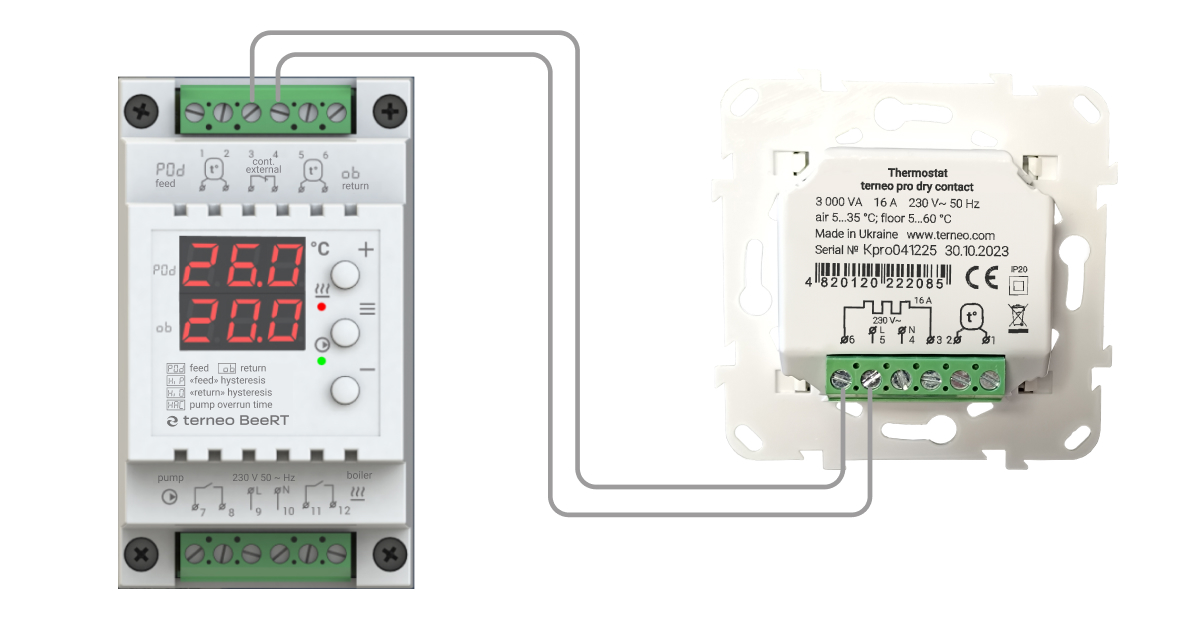

If the automation of your electric boiler is implemented using the terneo BeeRT thermostat, you can enhance comfort and efficiency by connecting the weekly programmer terneo pro dry contact to it, as shown in the figure below.

The installation requirements for the thermostat are similar to those applied for gas boilers. Terminals 5 and 6 of the terneo pro dry contact thermostat are connected to terminals 3 and 4 of the terneo BeeRT thermostat.

Figure 3. Connecting terneo PRO dry contact to terneo BeeRT

Heating System Configuration

After mounting and connecting the thermostat, supply power to both the thermostat and the boiler. Next, you need to configure the system and check its correct operation.

Main thermostat settings:

- Select the "Maintain temperature by air sensor" mode in the settings.

- Set the connected load power to the minimum (100 W). This is necessary for the correct measurement of air temperature using the built-in sensor.

- To save electricity, create a weekly schedule so that during your absence, the boiler maintains an economical temperature. Additionally, configure the Open Window, Preheating, and other settings for the comfortable operation of the heating system. Detailed instructions can be found in the terneo pro dry contact thermostat manual.

If you are using an electric boiler together with the terneo BeeRT thermostat, make sure to enable the "nc" contact function in the terneo pro thermostat settings. When the "nc" contact function is enabled, the terneo pro thermostat will open the contact on terminals 3 and 4 of the terneo BeeRT thermostat to reach the set air temperature in the room, and will close it once the temperature is achieved.

Main settings for the boiler

- Set the boiler temperature above average, for example, 60 °C. This is necessary for the thermostat to reach the desired temperature in the room even in the case of sharp outdoor temperature fluctuations.

- If you're using an electric boiler with the terneo BeeRT thermostat, it's recommended to set the thermostat settings above average, for example, setting the return water temperature to 60 °C.

5 advantages of controlling the boiler with the terneo pro thermostat with dry contact:

- Energy savings up to 50% due to operation according to a weekly schedule. You can set up to 16 temperature periods per day, maintaining a lower temperature when no one is home.

- Comfortable room temperature due to the boiler's operation to maintain the actual air temperature inside the room. Factors like outdoor temperature changes, heat loss inside, etc., are considered.

- Increased boiler lifespan by reducing the frequency of on/off cycles (cycling).

- Intuitive and user-friendly interface of the thermostat.

- Energy consumption statistics.

Connecting an external programmer to your gas or electric boiler is a step towards more efficient and convenient heating management in your home. The intuitive interface and numerous additional functions for energy savings.